Machine Performance Monitoring

at the Next Level

at the Next Level

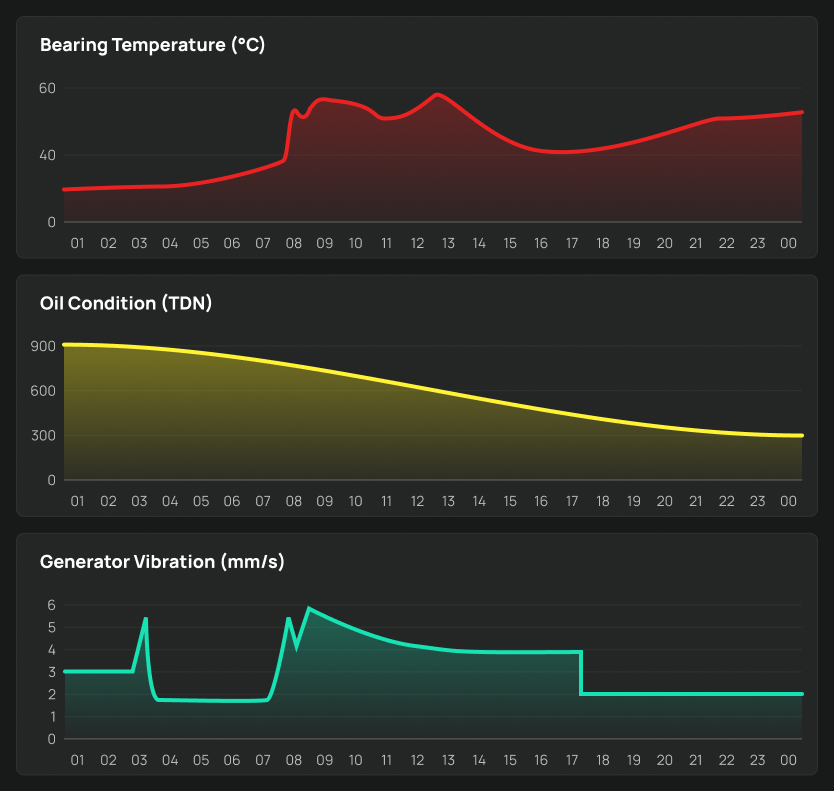

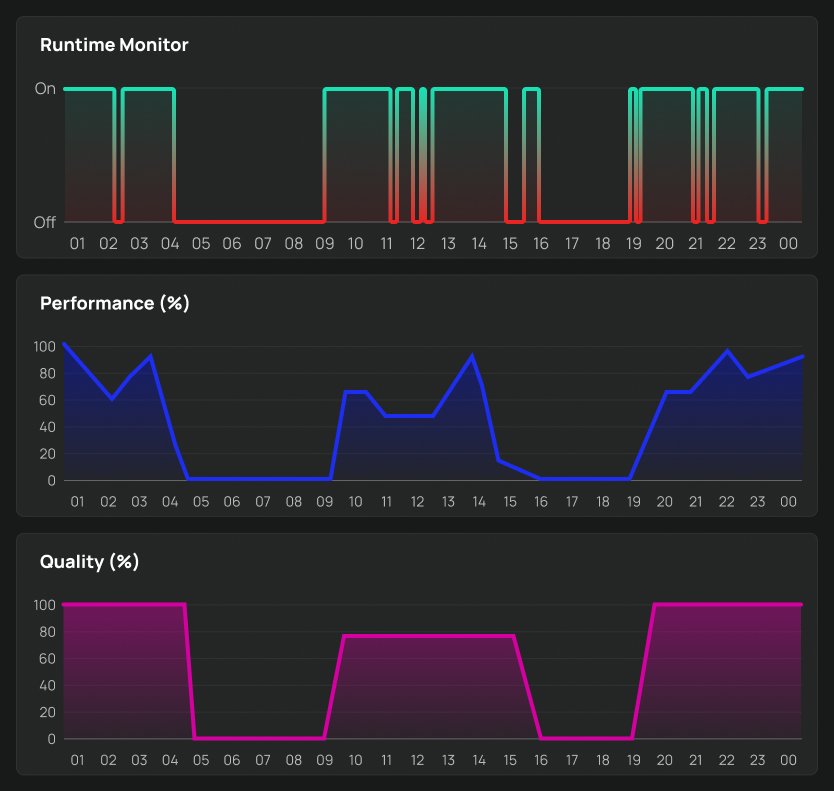

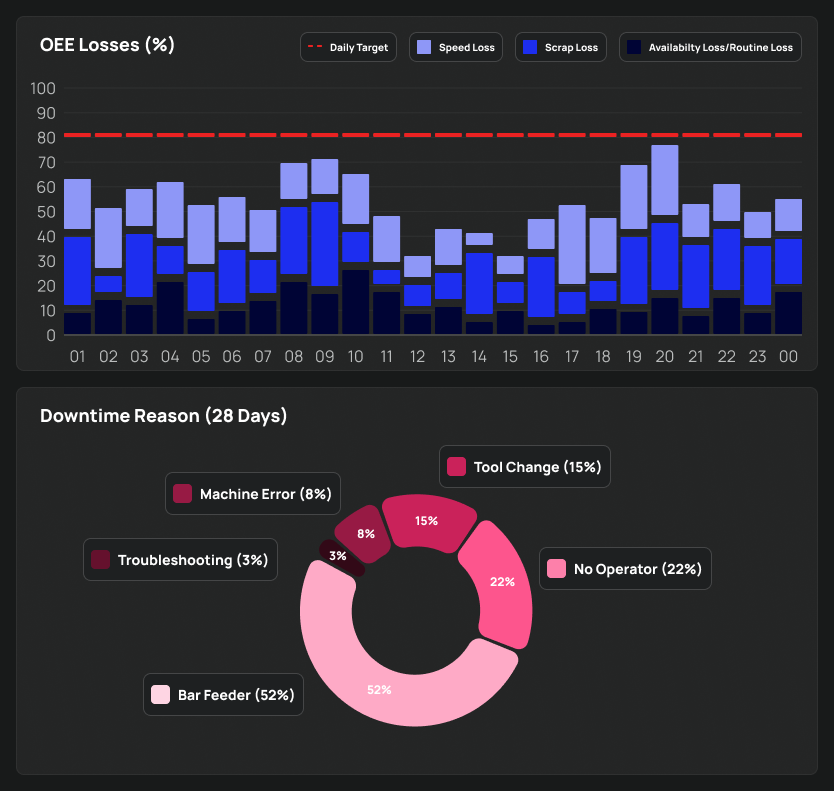

At ADG, we provide real-time, automated manufacturing analytics. Using advanced sensor technology and a modular software platform, we deliver a transparent Performance View of your operations accessible from anywhere.